EA engines custom intake manifolds?

EA engines custom intake manifolds?

Hi guys

Im new to the forum but have been reading and gathering information for some time on the mighty subaru L series. I have decided to get one of these superb machines for myself.

I have attempted to find info using the search function for anyone who has put together a custom intake manifold for the EA series engine with no luck.

I have good mechanical and fabrication skills and read how lousy the factoy item is with the coolant flowing through it and all. I have read over some aviation forums and websites about making your own carbon fibre inlet manifold but have yet to find a good pic or instruction on an automotive application inlet manifold. I prefer to work with metal than carbon fibre anyway and dont quite understand how the stuff works in such an application and even if it would be legal to be honest.

Does anyone have any info or made one up they could share some pics and performance differences from standard equipment or any links to automotive application preferably fitted to a L series with a weber carb hanging of the end of course or even twin carb custom set ups? I like making stuff and think it would be a good project and should be beneficial if researched and made properly.

Thanks for a great forum and take care.

Im new to the forum but have been reading and gathering information for some time on the mighty subaru L series. I have decided to get one of these superb machines for myself.

I have attempted to find info using the search function for anyone who has put together a custom intake manifold for the EA series engine with no luck.

I have good mechanical and fabrication skills and read how lousy the factoy item is with the coolant flowing through it and all. I have read over some aviation forums and websites about making your own carbon fibre inlet manifold but have yet to find a good pic or instruction on an automotive application inlet manifold. I prefer to work with metal than carbon fibre anyway and dont quite understand how the stuff works in such an application and even if it would be legal to be honest.

Does anyone have any info or made one up they could share some pics and performance differences from standard equipment or any links to automotive application preferably fitted to a L series with a weber carb hanging of the end of course or even twin carb custom set ups? I like making stuff and think it would be a good project and should be beneficial if researched and made properly.

Thanks for a great forum and take care.

- Gannon

- Senior Member

- Posts: 4580

- Joined: Sat Nov 05, 2005 10:00 am

- Location: Bowraville, Mid Nth Coast, NSW

The first thing the majority of members here are gonna suggest is do an EJ conversion (this entails replacing your EA82 with an EJ20/EJ22/EJ25 from a Liberty, Forester or Impreza

If you still wanna pursue with the EA82, id suggest either a low km engine, or rebuild yours to get the most out of your compression ratio.

Id then throw out your single inlet port heads and fit twin inlet heads from a MPFI touring wagon.

Then you have a reasonable platform to fit your custom intake and a well tuned webber carby.

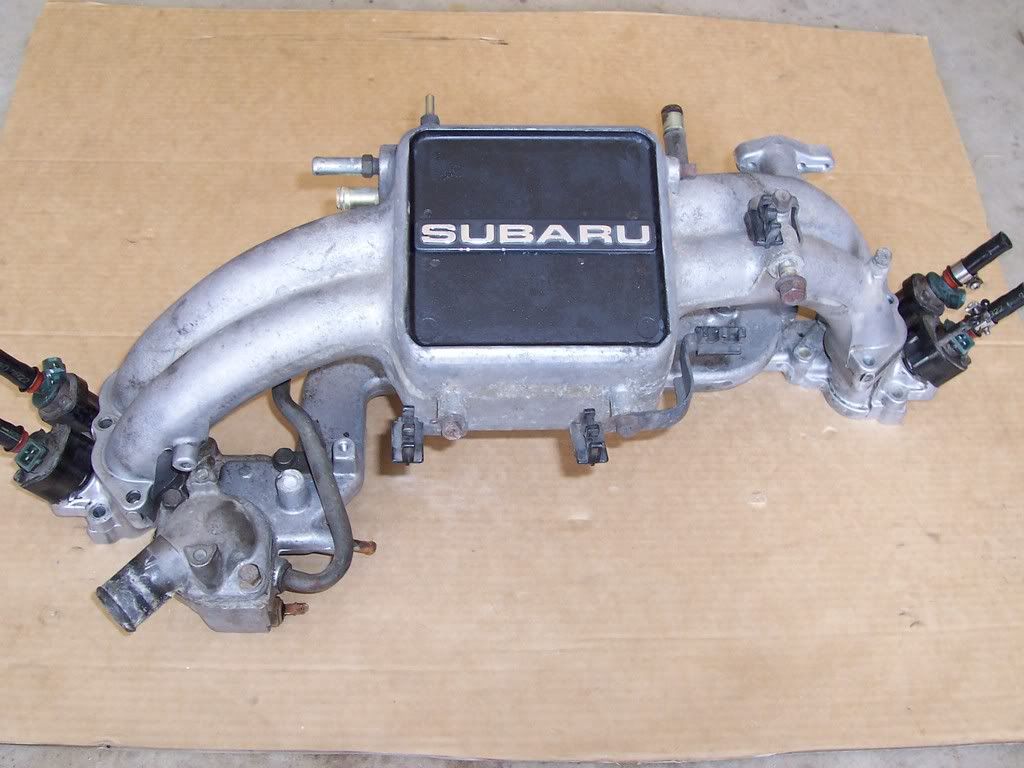

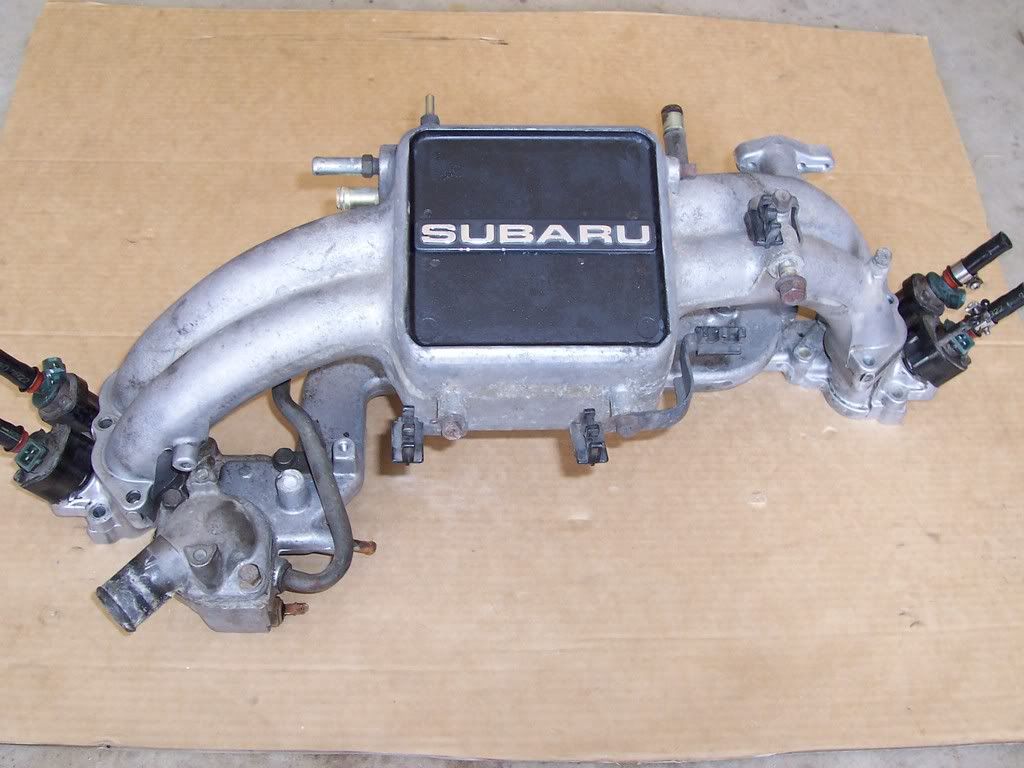

You could always fit an intake like this and mount a side draft SU carby or similar

(thanks to nncoolg for the images)

If you still wanna pursue with the EA82, id suggest either a low km engine, or rebuild yours to get the most out of your compression ratio.

Id then throw out your single inlet port heads and fit twin inlet heads from a MPFI touring wagon.

Then you have a reasonable platform to fit your custom intake and a well tuned webber carby.

You could always fit an intake like this and mount a side draft SU carby or similar

(thanks to nncoolg for the images)

Current rides: 2016 Mitsubishi Triton GLS & 2004 Forester X

Ongoing Project/Toy: 1987 RX Turbo EA82T, Speeduino ECU, Coil-pack ignition, 440cc Injectors, KONI adjustale front struts, Hybrid L Series/ Liberty AWD 5sp

Past rides: 92 L series turbo converted wagon, 83 Leone GL Sedan, 2004 Liberty GT Sedan & 2001 Outback

------------------------------------------

Ongoing Project/Toy: 1987 RX Turbo EA82T, Speeduino ECU, Coil-pack ignition, 440cc Injectors, KONI adjustale front struts, Hybrid L Series/ Liberty AWD 5sp

Past rides: 92 L series turbo converted wagon, 83 Leone GL Sedan, 2004 Liberty GT Sedan & 2001 Outback

------------------------------------------

- steptoe

- Master Member

- Posts: 11582

- Joined: Thu Oct 06, 2005 10:00 am

- Location: 14 miles outside Gotham City

keep the dream alive - research the Safari EA81 option of down draught weber on each head. You need to include a thermostat housing and no harm in using a rubber heater hose to join left to right custom manifold. I'd like to see someone make up a sand cast manifold incorporating the head to manifold ports and maybe a central thermostat housing borrowed from something else join up with heater hose.

I run a twin carb manifold on an EA81. SNORTED on petrol

. First time you see on you think you seeing double. The manifold will fit EA82 with minimal changes, small bit of a block needs trimmng.

. First time you see on you think you seeing double. The manifold will fit EA82 with minimal changes, small bit of a block needs trimmng.

Put out a wanted ad for EA81 twin carb set up and see what comes up ?? Careful not to get EA71 manifold , they are too short.

I run a twin carb manifold on an EA81. SNORTED on petrol

Put out a wanted ad for EA81 twin carb set up and see what comes up ?? Careful not to get EA71 manifold , they are too short.

That looks interesting and with the right mods it could be done. What is that intake of if you dont mind me asking (obviously Subaru but what model, engine size etc.)? It appears to have 2 runners on each side (4 all up) but I could be wrong it may be a single runner judging by how the runners appear to terminate into one flange on the ends (Im relatively new to Subarus so forgive me if Im wrong). I like the sidedraught carby idea and was playing with it as i have contemplated on ways to make up a custom inlet manifold for the EA series.

I would rebuild the engine before making a custom manifold and thought the EA81 would be a better engine to use. That way I can keep the car running while I put together a reconditoned and modestly modified engine then swap it over with minimal problems and distruption to having the vehicle taken off the road for long periods of time (drop it in over a weekend).

I like the EJ idea but the time and money needed for a proper upgrade is prohibitive for me at the moment. I much prefer to take my time and do up a EA81 slowly but good and thorough then drop it straight in. Im not really looking for serious performance just a little better than standard and do most of it myself except for the machining and valves etc. of course. I like making things and thought the inlet would be great project considering it could be made with nice long runners designed to house the carby where the spare wheel lives. Besides it shouldnt be difficult to improve on the original with all the available room under the bonnet when the spare is removed.

The manifold above is interesting and gives more food for thought, perhaps extending the runners and having it up where the spare wheel used to live could be a option. Let me know what its of so I can go see and measure one for myself.

While Im on the subject of mods I read somewhere that you cant shave too much of the cylinder heads as it effects the way it bots back up (EA81) and may not fit back together properly.

Can anyone with experience or in the know clarify this for me please as I want to bump up the compression if I can but within a comfortable limit of the engine and not on the edge of the heads limits if that makes sense?

I understand the MPFI EA82 pistons can increase compression to around 9.5:1 (correct me if Im wrong) but where do you find a decent set of those still on the conrods?

Thanks again for a great forum and more ideas to ponder.

I would rebuild the engine before making a custom manifold and thought the EA81 would be a better engine to use. That way I can keep the car running while I put together a reconditoned and modestly modified engine then swap it over with minimal problems and distruption to having the vehicle taken off the road for long periods of time (drop it in over a weekend).

I like the EJ idea but the time and money needed for a proper upgrade is prohibitive for me at the moment. I much prefer to take my time and do up a EA81 slowly but good and thorough then drop it straight in. Im not really looking for serious performance just a little better than standard and do most of it myself except for the machining and valves etc. of course. I like making things and thought the inlet would be great project considering it could be made with nice long runners designed to house the carby where the spare wheel lives. Besides it shouldnt be difficult to improve on the original with all the available room under the bonnet when the spare is removed.

The manifold above is interesting and gives more food for thought, perhaps extending the runners and having it up where the spare wheel used to live could be a option. Let me know what its of so I can go see and measure one for myself.

While Im on the subject of mods I read somewhere that you cant shave too much of the cylinder heads as it effects the way it bots back up (EA81) and may not fit back together properly.

Can anyone with experience or in the know clarify this for me please as I want to bump up the compression if I can but within a comfortable limit of the engine and not on the edge of the heads limits if that makes sense?

I understand the MPFI EA82 pistons can increase compression to around 9.5:1 (correct me if Im wrong) but where do you find a decent set of those still on the conrods?

Thanks again for a great forum and more ideas to ponder.

Thanks for the reply I was typing my second last post while you obviosuly submitted it and my second last remarks where aimed at the thread above it. However Im now going to check out the Safari EA81 as I havnt heard of that one.steptoe wrote:keep the dream alive - research the Safari EA81 option of down draught weber on each head. You need to include a thermostat housing and no harm in using a rubber heater hose to join left to right custom manifold. I'd like to see someone make up a sand cast manifold incorporating the head to manifold ports and maybe a central thermostat housing borrowed from something else join up with heater hose.

I run a twin carb manifold on an EA81. SNORTED on petrol

. First time you see on you think you seeing double. The manifold will fit EA82 with minimal changes, small bit of a block needs trimmng.

Put out a wanted ad for EA81 twin carb set up and see what comes up ?? Careful not to get EA71 manifold , they are too short.

The manifold above with extended runners angling back upto the spare wheel well has also got me thinking.

all the best fellas

how do i become a subscriber?

My avatar tells me Im not subscribed. Is there a fix for that that I havent realised as everyone else seems to be subscribers and I thought I was too.

cheers

cheers

the above is a highrise intake off an EA82 MPFI or Turbo engine out of a my88 on Vortex. The 2 port heads from the EA82 will not work on the EA81, but you can get very nice 4 port heads and EFI intakes for the EA81 from a mob called SUB4, definatley worth getting, almost worth downgrading from an EA82 to an EA81 to use them!

The trading corner : the stuff that I need ATM -

# Vortex Main Dash Surround / Bezel ANY COLOUR,

# Vortex Radio, # RHD Vortex 4speed auto digital dash,

# RH-Side parking (86+) Vortex wiper transmission,

# EA82 AWD 4EAT,

If you have them please PM me

# Vortex Main Dash Surround / Bezel ANY COLOUR,

# Vortex Radio, # RHD Vortex 4speed auto digital dash,

# RH-Side parking (86+) Vortex wiper transmission,

# EA82 AWD 4EAT,

If you have them please PM me

nncoolg wrote:the above is a highrise intake off an EA82 MPFI or Turbo engine out of a my88 on Vortex. The 2 port heads from the EA82 will not work on the EA81, but you can get very nice 4 port heads and EFI intakes for the EA81 from a mob called SUB4, definatley worth getting, almost worth downgrading from an EA82 to an EA81 to use them!

I have looked these up, but Im scared to ask for a price. I will eventually muster up the courage though.

- TOONGA

- Elder Member

- Posts: 5340

- Joined: Sat May 30, 2009 10:15 am

- Location: Mandurah where they divided by zero

- Contact:

in your user control panel is an option to a paid subscription (near the bottom of the list) basically when you subscribe you help pay for the hostimg of the site and it lets you post in the classified section and other areasDan. S wrote:My avatar tells me Im not subscribed. Is there a fix for that that I havent realised as everyone else seems to be subscribers and I thought I was too.

cheers

TOONGA

Here some links to a Brumby running the SUB4 dual port heads and manifold, although he says he's using the twin spark disctributor he only has pictures showing single spark with the secondary ones blanked off. Hopefully it gives you some ideas.

http://www.cardomain.com/ride/2271064

http://www.ultimatesubaru.org/forum/sho ... p?t=104550

http://www.cardomain.com/ride/2271064

http://www.ultimatesubaru.org/forum/sho ... p?t=104550

[SIGPIC][/SIGPIC]

- AlpineRaven

- Senior Member

- Posts: 3682

- Joined: Wed Oct 19, 2005 10:00 am

- Location: Melbourne, Victoria, Australia.

Ive seen this, its interesting and nice looking engineVenom wrote:Here some links to a Brumby running the SUB4 dual port heads and manifold, although he says he's using the twin spark disctributor he only has pictures showing single spark with the secondary ones blanked off. Hopefully it gives you some ideas.

http://www.cardomain.com/ride/2271064

http://www.ultimatesubaru.org/forum/sho ... p?t=104550

Cheers

AP

Subarus that I have/had:

1995 Liberty "Rallye" - 5MT AWD, LSD - *written off 25/8/06 in towing accident.

1996 Liberty Wagon - SkiFX AWD 5MT D/R, Lifted.. Outback Sway Bar, 1.59:1 Low Gearing see thread: 1.59:1 in EJ Box Page

Sold at 385,000kms in July 2011.

2007 Liberty BP Wagon, 2.5i automatic

1995 Liberty "Rallye" - 5MT AWD, LSD - *written off 25/8/06 in towing accident.

1996 Liberty Wagon - SkiFX AWD 5MT D/R, Lifted.. Outback Sway Bar, 1.59:1 Low Gearing see thread: 1.59:1 in EJ Box Page

Sold at 385,000kms in July 2011.

2007 Liberty BP Wagon, 2.5i automatic

- phillatdarwin

- Junior Member

- Posts: 532

- Joined: Thu Dec 25, 2008 6:11 pm

- Location: 93GL / 86rx ea82t Darwin NT

thanks for the comments and links. The sub4 heads are a little (or a lot) out of my league.

I have been doing some homework on intake manifolds and when I get time I have some formulas I have found to calculate optimum intake runner lengths and diameters for diffrent applications (low down torque up high end rpm etc).

I find engines fascinating and the Subaru boxer engine to be more interisting than inline 4's.

Im moving to North Queensland from Adelaide next month and just came inside about 1/2 hour ago from packing my shipping container. My life is vey busy at the moment but I will do some number crunching ASAP and start thinking about the best way to build one once I know how long and wide it should be (ideally).

Thanks for the all the help and info

Take care

Dan

I have been doing some homework on intake manifolds and when I get time I have some formulas I have found to calculate optimum intake runner lengths and diameters for diffrent applications (low down torque up high end rpm etc).

I find engines fascinating and the Subaru boxer engine to be more interisting than inline 4's.

Im moving to North Queensland from Adelaide next month and just came inside about 1/2 hour ago from packing my shipping container. My life is vey busy at the moment but I will do some number crunching ASAP and start thinking about the best way to build one once I know how long and wide it should be (ideally).

Thanks for the all the help and info

Take care

Dan

got dimensions worked out

after some time on automotive calculator websites I have come up with intake runner lengths and diameters.

I used the standard specs for an EA81 going of the 2400 rpm maxtorque and 4800 rpm max horsepower settings straight out of the Subaru manual. Of course a cam grind would change where the rpm of max torue and HP occurs and a new calculation would need to be made.

However in stock standard condition Im looking at a 1.5 inch inside diameter runner with a lenght of 29 inches from inlet valve to base of plenum. This provides the best intake for this size engine under the standard configuration.

I got quite a few diffrent answers that all pretty much close to each other. the diffrent answers weredue to diffrenr ways of working out the equation with Chrysler differng from pro engine and 5 other answers from diffrent manufacturers using diffrent methods to make the final calculation. I addde them all upand came up with an average of 29 inches.

The diameterseemed pretty constant between the two or three ways I used to come up with it as well as reading it on air plane build up somewhere that it needs 1.5 inches at the inlet port.

29 inches is massive but i believe if i were to get it that long it would need to snake around up to where the spare tyre lives. Which leaves with another question for you guys in the know.

Where can I get cheap 1.5 inch inside diameter pipe and angles made? other option is to use hose to make the angles or even water pipes for plumbing purposes but Im not sure on this idea.

I believe bending exhaust pipes causes a restriction at the bend and this what Im trying to avoid so any ideas into overcoming the restrictive bends and having a full 29 inches of 1.5 inch pipe with smooth unrestrictive angles would be apreciated.

I used the standard specs for an EA81 going of the 2400 rpm maxtorque and 4800 rpm max horsepower settings straight out of the Subaru manual. Of course a cam grind would change where the rpm of max torue and HP occurs and a new calculation would need to be made.

However in stock standard condition Im looking at a 1.5 inch inside diameter runner with a lenght of 29 inches from inlet valve to base of plenum. This provides the best intake for this size engine under the standard configuration.

I got quite a few diffrent answers that all pretty much close to each other. the diffrent answers weredue to diffrenr ways of working out the equation with Chrysler differng from pro engine and 5 other answers from diffrent manufacturers using diffrent methods to make the final calculation. I addde them all upand came up with an average of 29 inches.

The diameterseemed pretty constant between the two or three ways I used to come up with it as well as reading it on air plane build up somewhere that it needs 1.5 inches at the inlet port.

29 inches is massive but i believe if i were to get it that long it would need to snake around up to where the spare tyre lives. Which leaves with another question for you guys in the know.

Where can I get cheap 1.5 inch inside diameter pipe and angles made? other option is to use hose to make the angles or even water pipes for plumbing purposes but Im not sure on this idea.

I believe bending exhaust pipes causes a restriction at the bend and this what Im trying to avoid so any ideas into overcoming the restrictive bends and having a full 29 inches of 1.5 inch pipe with smooth unrestrictive angles would be apreciated.

- steptoe

- Master Member

- Posts: 11582

- Joined: Thu Oct 06, 2005 10:00 am

- Location: 14 miles outside Gotham City

maybe hoppers crossing was a bum steer, sorry.

Itwas .

Rising Sun Car Service small logo. Citizen Freeman trading as. Rising Sun Car Service 566 Main North Road Gepps Cross SA 5094 ... http://www.risingsuncarservice.com.au

Is it 29 inches divide by two for boxer engines. Steel suppplies, welding shops have little 90 deg bends in cast for welding hand rails or turbo exhaust manifolds etc. I made an inlet out of 50mm PVC pipe to the TB mounted on enlarged inlet manifold hole. The TB was too big - I used one off a 2.3 litre Volvo. Bogged down on take off but was torquey as my twin carb set-up.

Itwas .

Rising Sun Car Service small logo. Citizen Freeman trading as. Rising Sun Car Service 566 Main North Road Gepps Cross SA 5094 ... http://www.risingsuncarservice.com.au

Is it 29 inches divide by two for boxer engines. Steel suppplies, welding shops have little 90 deg bends in cast for welding hand rails or turbo exhaust manifolds etc. I made an inlet out of 50mm PVC pipe to the TB mounted on enlarged inlet manifold hole. The TB was too big - I used one off a 2.3 litre Volvo. Bogged down on take off but was torquey as my twin carb set-up.

No its 29 inches long per runner. Becuase of the siamese port design the diameter was doubled only. The length is what I came up with using this calculator http://www.wallaceracing.com/Calculators.htm It has a couple ways to do it as well as probably the most other engine calculators you could possibly want.steptoe wrote:maybe hoppers crossing was a bum steer, sorry.

Itwas .

Rising Sun Car Service small logo. Citizen Freeman trading as. Rising Sun Car Service 566 Main North Road Gepps Cross SA 5094 ... http://www.risingsuncarservice.com.au

Is it 29 inches divide by two for boxer engines. Steel suppplies, welding shops have little 90 deg bends in cast for welding hand rails or turbo exhaust manifolds etc. I made an inlet out of 50mm PVC pipe to the TB mounted on enlarged inlet manifold hole. The TB was too big - I used one off a 2.3 litre Volvo. Bogged down on take off but was torquey as my twin carb set-up.

I think I will do the rings, cam, crank and rod bearings and leave it standard apart from this manifold and the weber on top. Exhaust will probably be the next thing to get the little girls breathing in and out optimised for the standard cam. Apart from that I think the mods will stop there apart grom new plugs leads rotor dizzy cap etc. And maybe some form of snorkel for cold air intake.

Thanks for the help and advice guys and take care.