Modified caster plate to Xmember Lift

- stamp_licker

- General Member

- Posts: 1066

- Joined: Wed Oct 05, 2005 10:00 am

- Location: Kallangur.Bris North

Modified caster plate to Xmember Lift

Alrighty.This thread will be about the building of new caster plate to x Member lift blocks.The aim is to spread the load across 2 of the caster plate holes and then up to the engine crossmember lift blocks,before the captive nuts rip out.

If you have a look at the caster plate 2 of the holes are in direct line with the rod,not much guessing were most of the force goes.The idea at this stage is to use a bit of the engineering from the style of kit that uses blocks welded and uses standard bolts but making it a bolt on without welding to the plate.I am going to use 1 piece of box section[size to be determined] bolted to the 2 holes,spacing required for alignment .The caster plate will be bolted to this[2 bolts per point,one for body to block one for block to plate] .the box will then be connected up to the crossmember spacer using smaller rhs in order to clear the brake lines and keep it compact.The third bolt will use standard lift block.The lift i'm working with is a 3".

Photos will come with progress.

Feedback appreciated.

Will

If you have a look at the caster plate 2 of the holes are in direct line with the rod,not much guessing were most of the force goes.The idea at this stage is to use a bit of the engineering from the style of kit that uses blocks welded and uses standard bolts but making it a bolt on without welding to the plate.I am going to use 1 piece of box section[size to be determined] bolted to the 2 holes,spacing required for alignment .The caster plate will be bolted to this[2 bolts per point,one for body to block one for block to plate] .the box will then be connected up to the crossmember spacer using smaller rhs in order to clear the brake lines and keep it compact.The third bolt will use standard lift block.The lift i'm working with is a 3".

Photos will come with progress.

Feedback appreciated.

Will

[SIGPIC][/SIGPIC]aka the_postie

Building a hardcore postie:D

Building a hardcore postie:D

- stamp_licker

- General Member

- Posts: 1066

- Joined: Wed Oct 05, 2005 10:00 am

- Location: Kallangur.Bris North

- stamp_licker

- General Member

- Posts: 1066

- Joined: Wed Oct 05, 2005 10:00 am

- Location: Kallangur.Bris North

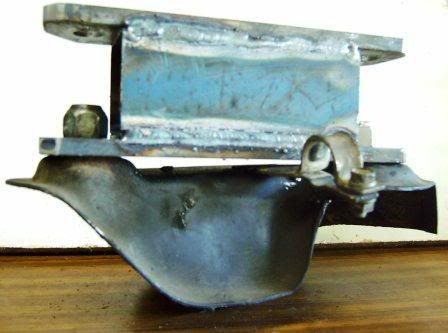

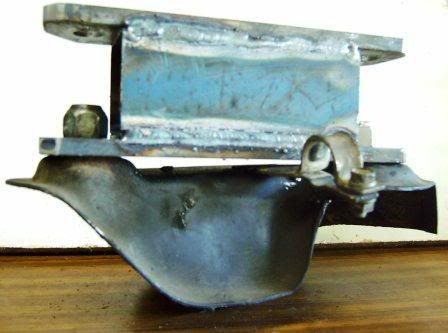

Nothing new here similar to the 6" stuff.The blocks can be done like this or a piece of rhs with crush tubes ,even solid alloy etc.Stage 2 is to connect this to the other block on the plate.If search around the net this has been done before some early design kits used rhs connected to tube ,rhs etc with flat bar.These blocks will be strong,but the more i look at the prob i don't want happening[captive nuts ripping out] i think checking all bolts are tight and even welding flat with new nuts internally as described by BYB and others over the years will stop it.Not trying to re invent the wheel so to speak.

These suckers are heavy ,rhs with crush tubes will be lighter.

These suckers are heavy ,rhs with crush tubes will be lighter.

[SIGPIC][/SIGPIC]aka the_postie

Building a hardcore postie:D

Building a hardcore postie:D

- El_Freddo

- Master Member

- Posts: 12677

- Joined: Tue Oct 04, 2005 10:00 am

- Location: Bridgewater Vic

- Contact:

Hey postie,

What exactly is crush tubing? I'm thinking of making my own lift kit now, i'm looking for ideas for strenght of the captive nuts as you've been talking about, i really liked what BYB01 was talking about with the floor idea.

More pics would be great.

And i'm a little confused as to how to make the strut tower lift blocks - what's the method here? 7mm towards the engine bay for every inch?

Cheers

Bennie

(Sorry about hijack)

What exactly is crush tubing? I'm thinking of making my own lift kit now, i'm looking for ideas for strenght of the captive nuts as you've been talking about, i really liked what BYB01 was talking about with the floor idea.

More pics would be great.

And i'm a little confused as to how to make the strut tower lift blocks - what's the method here? 7mm towards the engine bay for every inch?

Cheers

Bennie

(Sorry about hijack)

- stamp_licker

- General Member

- Posts: 1066

- Joined: Wed Oct 05, 2005 10:00 am

- Location: Kallangur.Bris North