Today I decided I would try and turn the engine over on the starter and get some oil pressure up, see if my oil gauge in the dash would do anything. Also to see if my starter motor was going to work

To that end the engine now has oil in it as well as the gearbox. I've plugged the L series tailshaft in the back sort of temporarily, in case any oil should spill out.

I've made up all my power distribution and starter cables with decent solid copper lugs and thick, glue lined heat shrink. Last week I measured all the bits out and cut them, then took the lot in to work and borrowed the big lug crimping tool. I think they look pretty good, all professional like

And literally half the price (or less) than the ready made ones you can buy at super crap. The cable could do with being one size smaller though, I bought this stuff in my first order of wire from when I was starting on the cars wiring and before I had any idea of cable cross section, so I didn't really know what I was buying. Still, too thick is better than not thick enough.

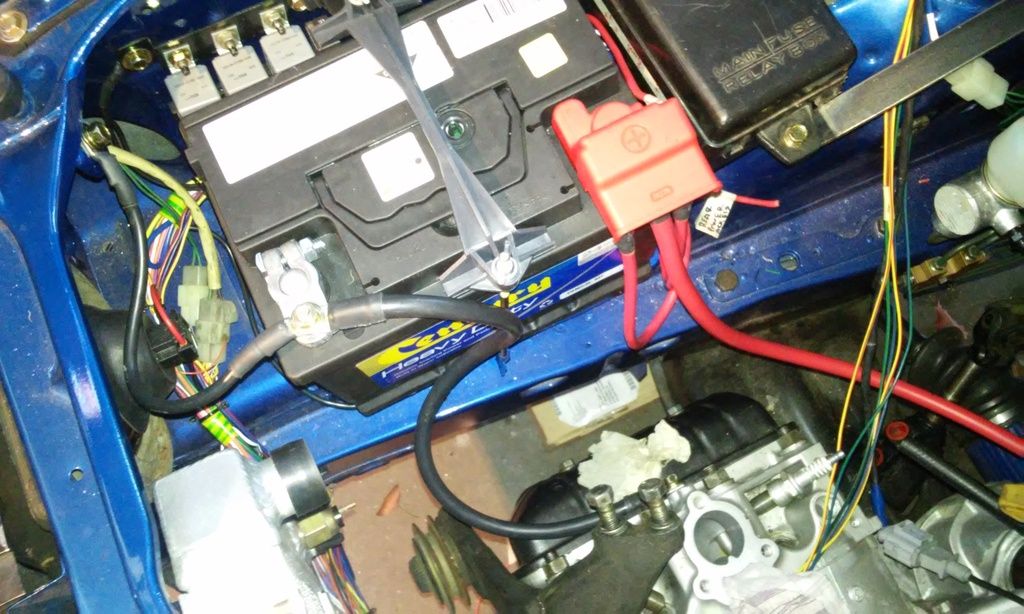

Got everything hooked up to how it will be at the end with nice new battery terminals. Everything still worked as it should electrically, the alarm went off (silently) when I put the negative terminal on.

When it came to the starter though, all was not well

I didn't hook it up straight away so I could put a multimeter between the cable and the starter post on the solenoid and measure if there was any current draw when there shouldn't be. The MM said there was .03 milli amps flowing, absolutely bugger all. So when I hooked up the starter cable to the motor I was surprised to see tiny tiny sparks jumping across when I put the lug to the post. Didn't think much of it at the time. I pulled all the spark plugs (and the rags from the intake holes

) and blipped the starter with the key - starter motor did nothing

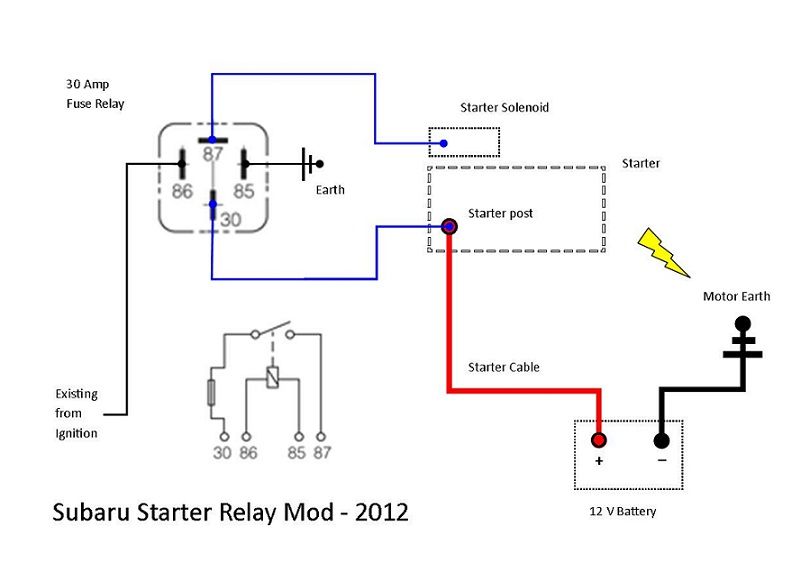

Had a suspicion I'd wired up the starter relay wrong so went to test my theory and yes I had it wired up wrong; the male spade on the starter solenoid wants ground to activate the starter motor itself, I had 12v+ going to it. It was about now I noticed the starter solenoid was almost too hot to touch

This starter motor was originally on my ute and died one day (wouldn't turn over) So I had to swap it with the one from this wagon which was in the shed (in the dark at 6AM) and so the original one from the wagon still lives in the ute. When I pulled the utes dead starter apart I found one of the bearings for the pinion shaft was MIA, so thought that was the culprit (the motor shaft jamming and stalling the starter) It seems though that wasn't the only problem. Anyone have any ideas about this problem? Do I need a new solenoid?

Letting it cool down and with the solenoid "trigger" wire disconnected, I touched the starter cable to the post again to double check and the solenoid started getting warm straight away, bugger!

Interestingly when I tested my wiring fault by putting a grounded wire to the male spade, the starter kicked into life and turned the engine over beautifully, but obviously there's something wrong inside still.

. There's a reason you don't see it used from the factory ...