RCA cables taped up and sorted out. Had some screw in cable tie mounty things which came in handy. Can also see the DCCD g-sensor next to the handbrake. Oh and the DCCDPro controller under the stereo where the factory airbag controller would be if I had any.

DCCD cables fixed down and neatened up a little.

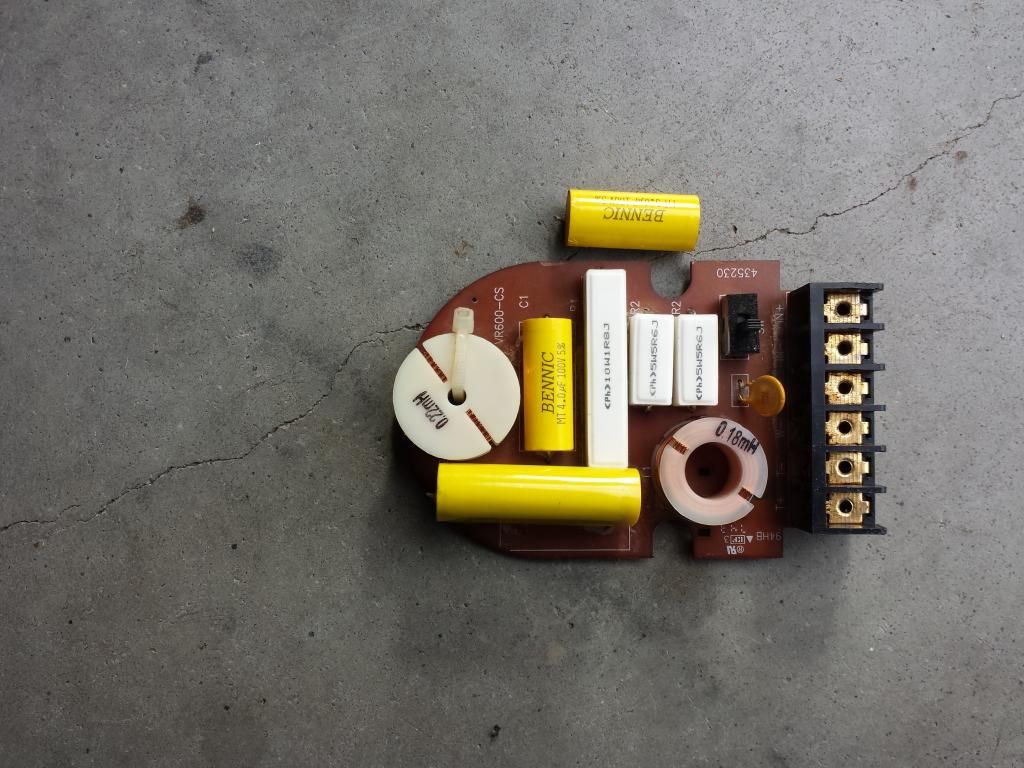

Crossovers moved from inside the door. Positioning isn't great, fouls on the interior door panel by about 5mm. Might move it later when I redo the plastic door linings.

DCCD cables hidden away nicely.

Same with the RCA leads.

Found this bung had been knocked out and was letting water in. Replaced it with a rubber one I had.

Water also had come in through this hole. I drilled this out to access a broken captive nut on the trailing arm mounts. Will sort out something for it later.

This crossover position worked out better.

Seats and sill trims all refitted. Stereo cables have all just been run to the back and ready to wire up another day.

Going carpet-less for a while to see how I like it. May end up doing a bed liner. I like the idea of been able to see any water for an easy clean up.