Page 1 of 1

Subaru tailshafts / slip yoke / one piece

Posted: Wed May 16, 2012 5:52 pm

by stenno

Hi all,

Im looking at having to get a "one piece" tailshaft made. L 5 speed into brumby.

Rather than getting my brumby one piece cut and lengthened (cost & balancing issues), im trying to find something else with the same slip yoke specs that can simply be cut down to the right length (cheaper and stronger). Also id like to have rebuildable unis that isnt possible with a subaru tailshaft. (i think??). Id prefer not to use a 2 piece shaft without having to fabricate a "subi boys spec" tailshaft bearing mount.

Subaru front yoke "specs" (ea81 4 speed, Ea82 5 speed, EJ22 auto, STI 6 speed checked)

22/24 (22 teeth total, 11 teeth then 1 tooth space then 11 teeth then 1 space) 15mm setback of spline from snout, 80mm of spline internal.

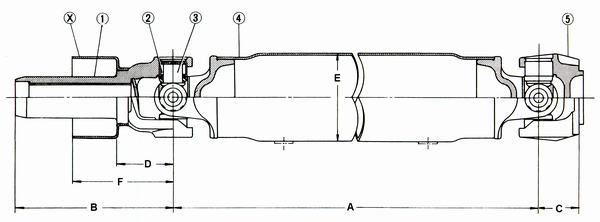

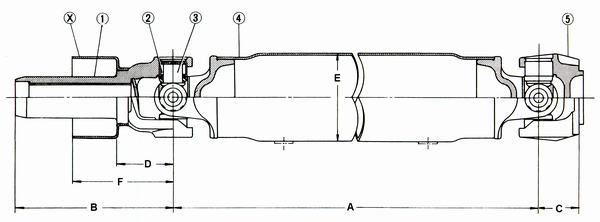

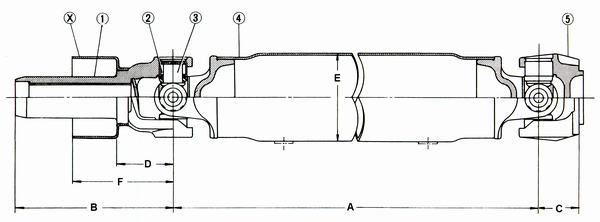

Subaru tailshafts approx specs

Model, "B", "A", "C"

EA81 4 speed, 150, 1140, 35

EA82 5 speed, 140, 1360 (620+740), 40

EJ22 Auto, 135, 1355 (585+770), 35

EJ20 6 speed, (same as ej22 Auto)

"research" has led me to here;

http://www.drivetrain.com/parts_catalog ... ssion.html and

https://www.powertrainindustries.com/PD ... _parts.pdf page 44.

That datsun / nissan use the same transmission yoke and hopefully still use a R160 diff yoke (otherwise swapping an R180 diff snout plate isnt hard). Datsun ute unis are apparently replacable but sedan ones arent.

but, the only datsun tailshaft details i could find were on here:

datsun1200.com wiki

None long enough, damn

Anyone know / heard of someone using a datsun tailshaft cut down? what model it was off? Or something else that could be cut down?

Posted: Fri Jun 01, 2012 6:43 pm

by Silverbullet

This thread just became relevant to me; bought an L series 5 speed this week for the wagon. Johnno says mounting the L series bearing carrier isn't hard, but I don't have an aptitude for lining things like this up correctly and a 1 piece shaft sounds better to me for some reason. Not to mention I don't have an L series tailshaft

Just wondering, what's involved in lengthening the stock tailshaft? is it just a matter of measure, cut, weld in some thick walled pipe and check for balance/run out? if it's that simple I know someone who could probably do the work.

Posted: Fri Jun 01, 2012 6:50 pm

by Cliff R

stenno.

What an excellent question and well thought out presentation you have asked.

I too dont have an answer but am mighty interested as EA81 gearboxes in good nick are very far between and I suspect mine is stuffed anyway so an EA82 box looks good.

Is a mod like this likely to need an engineering certificate

Posted: Fri Jun 01, 2012 10:32 pm

by stenno

I have been away on holidays for a while and laptop with all the saved info but from what I can recall in regards to tailshafts; bearing in mind I haven't been to the wreckers with a tape measure yet only "Internet" knowledge.

Almost every suitable factory one piece tailshafts are shorter than needed for a L series 5 speed into my. This is cause of nvh issues for factory manufacturers and also inherent resonance / whip issues in a 1 piece shaft by design. McDonald bros fabrications I think have a very usefull chart on their website shown material type / size / thickness and safe peak rpm of a shaft.

A variant of the Toyota t50 gearboxes (jap spec ae86 sprinter) had the same gearbox splines but no dust cup, slightly longer in length tip to uni than a Subaru spec one. Handy as a shorter "shaft" is then needed. I'm unsure on how this will effect "body" clearance.

This takes a re build able uni joint that is common to early Toyota ae corollas (ae25 on), coronas etc. these cars have the same size or slightly thicker wall size and od as a Subaru 1 piece tailshaft and approx the "right length".

All toyota tailshafts take / have different diff flanges to Subaru / Nissan r160 diff flanges so this would need to been cut off and changed to a Subaru flange / uni and re welded or possibly a "rebuild able" Nissan diff flange to uni joint maybe compatible to the toyota tailshaft uni. A bit more research need to be done on this to hopefully get a "workable" solution.

Realistically, I can't see a "remove this circlip, swap on this joint here, replace the circlip and wallah it bolts on perfect" solution (I'm hoping for one, but then again I also buy the odd lotto ticket too), but I know going somewhere and saying "custom" seems to add an extra zero to the bill, rather than walking in with the parts and saying "I need "x mm" length cut out, rewelded and balanced, which should hopefully see a turn around time measured in days rather than weeks and a stack cheaper bill too. Having all rebuild able joints would make future maintenance costs a case of only buying a "xxxx part number" uni joint and swapping it in rather than a brand new shaft made too.

Posted: Fri Jun 01, 2012 10:50 pm

by discopotato03

Early Datsuns used the same output shaft spline as older Subarus do . I had a two piece tailshaft made for my RX L Series and it uses all Holden rebuildable uni joints . The front slip section is from an old 80's Bluebird and takes the same uni spiders .

The trouble with one piece tailshafts is they need to be big in diameter if they are long to have the cross sectional stiffness . Often two piece shafts are used so they can more easily follow the floorpan shape and be smaller in diameter .

You may find it easier to start with an old Holden tailshaft thats longer than yoo need and get a specialist to shorten it .

Talk to a driveline firm , cheers A .

Posted: Fri Jun 01, 2012 10:51 pm

by stenno

Silverbullet wrote:Johnno says mounting the L series bearing carrier isn't hard, but I don't have an aptitude for lining things like this up correctly and a 1 piece shaft sounds better to me for some reason. Not to mention I don't have an L series tailshaft

Just wondering, what's involved in lengthening the stock tailshaft? is it just a matter of measure, cut, weld in some thick walled pipe and check for balance/run out? if it's that simple I know someone who could probably do the work.

yep, in theory mounting them is as simple as running a bit of string here to there and drilling holes at the right stop. Practically well it's probably a bit harder than that.

Lengthening a one piece can be done two ways; as you described or both ends of the existing shaft are cut off and a new "full length" shaft welded in between the ends. A tailshaft failure is right up there in the catastrophic / life threatening things that go wrong (just google images and YouTube tailshaft failure / breakage / snapping if you don't believe me) so I'd be wary of not getting an expert or at least someone who had done something similar and had the right tools to do it.

Posted: Fri Jun 01, 2012 10:59 pm

by stenno

Cliff R wrote:stenno.

What an excellent question and well thought out presentation you have asked.

I too dont have an answer but am mighty interested as EA81 gearboxes in good nick are very far between and I suspect mine is stuffed anyway so an EA82 box looks good.

Is a mod like this likely to need an engineering certificate

Technically you need a certificate because you need to modify the crossmember for the tranny, but the only work that needs to be done is a bit of plate welding on the backside of the existing crossmember and some holes drilled. If welded properly I personally won't be worrying about it but you may run into that one in a million cop or insurance assessor who would pick it up, then you'd have some explaining to do.

Posted: Fri Jun 01, 2012 11:13 pm

by stenno

discopotato03 wrote:Early Datsuns used the same output shaft spline as older Subarus do . I had a two piece tailshaft made for my RX L Series and it uses all Holden rebuildable uni joints . The front slip section is from an old 80's Bluebird and takes the same uni spiders .

The trouble with one piece tailshafts is they need to be big in diameter if they are long to have the cross sectional stiffness . Often two piece shafts are used so they can more easily follow the floorpan shape and be smaller in diameter .

You may find it easier to start with an old Holden tailshaft thats longer than yoo need and get a specialist to shorten it .

Talk to a driveline firm , cheers A .

Uni spiders, that's the term I've been trying to think of. And thanks for imparting some of your knowledge disco, I was hoping you'd post sooner or later.

Closest thing to a driveline firm here in the country is a 24hr truck repair workshop with all the gear or an auto trans joint that sends out anything other than a flush or swap job.

I'm probably months away from that far getting the ute together yet but it's not something I want to bodge up myself. An expert will be found

Posted: Fri Jun 01, 2012 11:56 pm

by Silverbullet

Further discussion with my engineer this evening has made up my mind; 2 piece tailshaft is the way to go. Apparently shortening a tailshaft is quite simple, but lengthening is a completely different story. Because you'd need to weld a new section in, the very process of welding will pull the shaft out of alignment and cause balance issues. Balancing is also quite difficult apparently.

Compared to mounting the center bearing carrier where alignment isn't as critical (can be 2 inches out of alignment and it won't matter) as long as it is reasonably correct lengthways.

Looks like I'm looking for an L series tail shaft/s now, custom 1 piece shafts made from original are too complicated/costly.

Posted: Sat Jun 02, 2012 9:05 am

by steptoe

pull string tight and straight - anywaay, i am no engineer, don't centre bearings change the power direction a bit ! Four unis per shaft ?

I think I stretched my string out at about midnight after about 11 hours on the job, drove it home 4 hours later, so by then was tired and cranky and not in mood to play with string lines but wasn't walking home in the cold. With no insulation boot, hearing the noise of box concerned me for no good reason. So, fit al bots before driving to save same concern you were sold a dud !

Don't let me mislead anyone - I was using a 2 post hoist with the pesky lump on the floor for the cables (got in the way of trans lifter) and my 17 hour midnight marathon also involved chasing a second rear main oil seal coz I stuffed the first one putting it in, just fitting my preprepared [looks as silly as it sounds ! ] pedal box with L cable mount block fitted in nicely.

And chop the bloody useless threaded boss off top rear right hand side that hits Brumby floor !

No mods requird to MY cross member just elongate holes of MY mount plate that bolts directly to L box. One hole is elongated outways, away from its brother, the other inways, towards its brother. End up with MY crossmember not even touched, MY gearbox mounts, MY gearbox 'mount to gearbox plate' ever so sligtly drilled out a bit and an L gearbox in 5 speed DR. Do what you like with old box and piec of string

Search Disco's posts who had Torana XU1 ? unis fitted to his L shaft if really think it neccesary [they have more detail than imparted above]

Posted: Sat Jun 02, 2012 9:14 am

by steptoe

NSW RTA consider this an owner certified modification if I read rules correctly.

Gees guys, material for more Whimpy Kid series ?? You remind me of all the questions I asked, and asked, and got confirmed, raised more questions, got some pics as proof - then when I did it, humph, the local Sube specialist wanted $1500 to do it if he did it again - even he did not know to use the L tailshaft!!Lucky for m , all those questions wre raised pre old AUSubs storage demise

Posted: Sat Jun 02, 2012 11:14 am

by Silverbullet

steptoe wrote:NSW RTA consider this an owner certified modification if I read rules correctly.

Gees guys, material for more Whimpy Kid series ?? You remind me of all the questions I asked, and asked, and got confirmed, raised more questions, got some pics as proof - then when I did it, humph, the local Sube specialist wanted $1500 to do it if he did it again - even he did not know to use the L tailshaft!!Lucky for m , all those questions wre raised pre old AUSubs storage demise

I'm only asking because I can't find a decent "How to" thread on the 5speed into MY conversion with decent pics. I'll be making one when I get round to it so you won't have to suffer any more new members whimpy-ness

Posted: Sat Jun 02, 2012 5:55 pm

by steptoe

ask , send me your email and I'll shoot mine through ..think still have it in copied to paper form......